Product Description

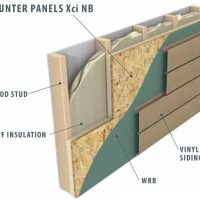

Designed for continuous insulation, Thermax (ci)’s foam core is homogenous – featuring finer cell size and better cell orientation, reducing voids and knit lines – resulting in one of the highest R-values(2) available for immediate insulation and weather protection on the job site, as well as long-term thermal performance.

Thermax (ci)’s integral durable thermoset coated aluminum facer provides a drainage plane and water resistive barrier, eliminating the need for a membrane or building wrap when used in conjunction with DuPont Flashing Products. With its low perm rating and high insulating value, Thermax (ci) helps reduce the potential for condensation within the wall assembly. Thermax (ci) is also manufactured using a distinct free-rise technology using a unique fiberglass core for better product consistency, durability than generic polyisocyanurate insulations.

Ease of Installation

Thermax XARMOR (Ci):

- Eliminates the extra step of installing a separate membrane or building wrap when used with DuPont LiquidArmor and DuraGard

- Contains UV-stable technology – can remain uncovered up to six months

- Is optimized to go behind rain screen exteriors

- Helps reduce the potential for condensation within the wall assembly

- Is lightweight – easy to cut, handle and install

Available Sizes

Sizes, R-values and edge treatment options for Thermax (ci) can be found in Table 1 of the TDS located in the tab below. Contact your local sales representative for additional sizes.

Sustainable Solutions

Thermax (ci) Exterior Insulation is manufactured with a zero ozone depleting potential blowing agent. The use of Thermax brand insulation helps reduce the carbon footprint of commercial buildings. Thermax is compliant with California Department of Public Health (CDPH) VOC emissions requirements.

Physical Properties

Property and Test Method Value

Compressive Strength(2) , ASTM D1621, psi 25.0

Flexural Strength, ASTM C203, psi 40 min.

Dimensional Stability, ASTM D2126 0.2% max

Water Absorption, ASTM C209, % by volume, max. 0.1

Water Vapor Permeance, ASTM E96, perms <0.01

Maximum Use Temperature, °F 250

Light Reflectance, Visual Light Spectrophotometer, % 65

Surface Burning Characteristics(3), ASTM E84 for

both foam core and finished product Class A

Flame Spread 25

Smoke Developed <450

Applicable Standards

Thermax (ci) meets ASTM C1289 – Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board, Type I, Class 2. Applicable standards include:

- C203 – Standard Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

- C209 – Standard Test Methods for Cellulosic Fiber

Insulating Board - C518 – Standard Test Method for Steady- State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

- D1621 – Standard Test Method for Compressive Properties of Rigid Cellular Plastics

- D2126 – Standard Test Method for Response of Rigid Cellular Plastics to Thermal and Humid Aging

- E96 – Standard Test Methods for Water Vapor Transmission

of Materials - D1623 – Standard Test Method for Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics)

Notice

Thermax (ci) complies with the following codes:

- ASTM E2178 Standard Test Method for Air Permeance of Building Materials – leakage rates less than 0.001 L/s/m2 at

a test pressure of 75 Pa. - ASTM E2357 Standard Test Method for Determining Air Leakage of Air Barrier Assemblies

- ASTM E331 Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference

- 2021, 2018, 2015, 2012, and 2009 International Residential Code (IRC) Section 316

- 2021, 2018, 2015, 2012, and 2009 International Building Code (IBC) Section 2603. Contact your DuPont sales representative or local authorities for state and local building code requirements and related acceptances.

- 2019 California Green Building Standards Code

- 2020 ICC 700 National Green Building Standard

- Thermax™ products are covered under Underwriters Laboratories Inc. (UL) File R5622

- UL 1256 – Fire Test of Roof Deck Constructions, Roof Deck Construction No. 120 and No. 123

- Class A UL 723 (ASTM E84) Surface Burning Characteristics

of Building Materials - Intertek CCRR-0435

- The following designs are 1, 2, 3 or 4 hour wall rated assemblies as listed in the UL Fire Resistance Directory:

U026, U326, U330, U354, U355, U424, U425, U460, U902,

U904, U905, U906, U907, V454, V482, V499 - NFPA 285 compliant when installed as part of exterior wall assemblies in CCRR-0435 or valid engineering

judgement reports - Miami-Dade County approved

General Insulation Company Inc. is an insulation supplier / insulation distributor that stocks and fabricates a wide variety of industrial and commercial air barrier, vapor barrier, moisture and water barrier products for the construction market.